Softner WNS 3020F (Non ionic softner)

Softner WNS 3020F (Non ionic softner) Specification

- Chemical Name

- Non Ionic Softener

- Other Names

- WNS 3020F

- Type

- Textile Softener

- Application

- Textile Industry, Garment Finishing, Yarn Softening

- Application Method

- Padding, Exhaust, or Spray Method

- Feature

- Excellent Softness, Non-yellowing, Improves Handle & Lubricity, Compatible with Optical Brighteners

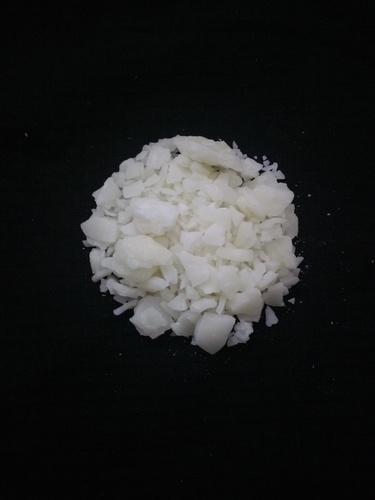

- Appearance

- Light Yellow to White Paste

- Raw Material

- Fatty Acid Derivative

- Physical State

- Paste

- Usage

- Provides smooth, soft & bulky handle to fabric

- Shelf Life

- 6 Months

- Ingredients

- Blended Fatty Acid Derivatives and Emulsifiers

- Solubility

- Easily Dispersible in Water

- Purity(%)

- 98%

- Toxicity

- Non-toxic and eco-friendly

- Odor

- Mild/Characteristic

- Stability

- Stable to hard water and acids

- pH Value

- 5.0 - 7.0 (1% Solution)

- Ionic Nature

- Non-ionic

- Packing

- 50 kg HDPE drum

- Compatibility

- Compatible with cationic, non-ionic and anionic auxiliaries

- Storage Conditions

- Store in cool, dry place, away from sunlight

- Dosage

- 0.5% - 2% owf (on weight of fabric)

Softner WNS 3020F (Non ionic softner) Trade Information

- FOB Port

- Mundra / Nhava Sheva

- Payment Terms

- Letter of Credit at Sight (Sight L/C), Telegraphic Transfer (T/T), Cheque

- Sample Available

- Yes

- Sample Policy

- Contact us for information regarding our sample policy

- Packaging Details

- As per Product Like Box Packing, Bag Packing, Plastic Drum

- Main Export Market(s)

- Australia, North America, Eastern Europe, Middle East, Western Europe, Africa, Central America, South America, Asia

- Main Domestic Market

- All India

About Softner WNS 3020F (Non ionic softner)

Softner Wns 3020f

Softener WNS 3020F (Non-ionicsoftener) is a softener which is not diluted from the flakes or cake but formulated to achieve lumpy and elastomeric finish. It can be used for cotton, polyester/cotton fabrics. It has a very good hand feeling and anti-static properties.This can be diluted to make ready to use a softener for cotton, viscose, polyester, acrylics and their blends.Softener WNS 3020F (Non-ionic softener)imparts excellent softness on the treated substrates. This softener does not carry any electrical charge and therefore do not po-ssess any distinctive substantivity. This softener is perfect for finishing optically brightened high-white articles. This softener also imparts lubricity to yarn and antistatic protection during spinning resulting in trouble-free operation

Composition :

- Fatty Acid Ester

Description :

Softnerwns 3020f Is Low Cost Nonionic Concentrated Softener Of Cellulosic And Their Blend. It Imparts Non-Yellowing, Mooth And Slippery Handle To The Fabric.

Chemical & Physical Characteristics

- Colour And Appearance : White To Cream White Soft Flakes.

- Nature : Non Ionic

- 20% Dispersibility : Smooth Thick Paste.

- Concentration : 98.0

Functionality Application

- Textile Industries : Non-Ionic Softener For Cotton And Blends.

- Product Attribute

- Give Soft Feel To Cellulosic And Polyester.

- Compatible With Cationic And Anionic Surfactants.

- Stable To Hard Water.

- Improves The Tear Strength And Abrasion Resistance In Cellulosic.

- Compatible With Resins.

- Specially Suited For White Fabrics.

Procedure To Get Diluted Product

For Preparing 100 Kgs Of Diluted End Product - Add With Constant Stirring 20 Kgs Of Softnerwns 3020f To 80 Kg Of Water Heated Up To 70 -80 Deg C And Stir For One Hour (90 - 100 R.P.M.), Cool And Use The Product For Finishing.

Direction For Use Of Diluted End Product

The Diluted Product Can Be Used By Exhaust And Pad Application For Finishing Of Textile Substrates Like Polyester, Cellulosic, Wool And Their Blends.

Dosage :

- 5 To 10 Gpl For Soft And Smooth Hands.

- 5 To 10 Gm/Ltr (Softener In Resin Finishes)

- Ph Of Application : 4 - 5 For Cellulosic

- 6 - 7 For Polyester

Packaging / Storage / Safety

Packaging : 25 Kg.

Storage : Protect From Extremes Of Temperature

Shelf Life : 12 Months From Date Of Manufacturing In Original Sealed Container.

Protective Clothing : Normal Precautions For Handling Chemicals Should Be Applied Including The Wearing Of Protective Clothing, Hand Gloves & Safety Goggles.

Enhanced Fabric Softness and Versatility

WNS 3020F is ideal for the textile industry, delivering a smooth, soft, and bulky touch to fabrics. Its non-ionic nature ensures broad compatibility with most textile auxiliaries, while its stability in hard water and acidic environments enhances process reliability. The softener is easily dispersible and non-yellowing, making it suitable for a range of finishing applications, including garments and yarns.

Easy Application and Storage

This softener can be conveniently applied using padding, exhaust, or spray methods, allowing flexibility across different finishing lines. It should be stored in a cool, dry place, away from direct sunlight, and retains optimal performance for up to 6 months when stored correctly. Its packaging in sturdy 50 kg HDPE drums ensures safe transportation and storage on-site.

FAQs of Softner WNS 3020F (Non ionic softner):

Q: How is Softner WNS 3020F typically applied in textile processing?

A: WNS 3020F can be applied using the padding, exhaust, or spray method, which allows it to penetrate and soften textiles effectively. The recommended dosage is between 0.5% and 2% based on the weight of the fabric.Q: What fabrics and processes can benefit from using WNS 3020F?

A: This non-ionic softener is suitable for garment finishing, yarn softening, and general textile softening, providing an improved handle, increased smoothness, and a bulky feel to various fabric types.Q: What are the storage recommendations for Softner WNS 3020F?

A: Store the product in a cool, dry area, away from direct sunlight. Proper storage conditions will help maintain product efficacy for its shelf life of up to 6 months.Q: When should the softener be added during processing?

A: WNS 3020F should be added during the finishing stage of textile processing, either after dyeing or before the final rinse, depending on the desired result and chosen application method.Q: Is Softner WNS 3020F compatible with other textile chemicals?

A: Yes, it is fully compatible with cationic, anionic, and non-ionic auxiliaries, as well as optical brighteners, making it a flexible choice for diverse finishing formulations.Q: What are the main benefits of using WNS 3020F?

A: The softener imparts excellent softness, lubricity, and a pleasing hand-feel to textiles without yellowing. It is also eco-friendly, non-toxic, and safe for use in modern textile processes.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Textile Softners Category

Softner WNS 3021 L (Non Ionic Softener)

Application Method : Padding, Exhaust, Spray

Shelf Life : 12 months from date of manufacture

Type : Other, Non Ionic

Feature : Gives soft and smooth hand feel to fabrics, enhances fabric pliability

Solubility : Easily soluble in water

Other Names : Non Ionic Softener

Silico-Soft SUPERSIL 600 (Silicon Softener)

Application Method : Padding and exhaust method

Shelf Life : 12 months

Type : Other, Nonionic Silicone Softener

Feature : Provides excellent softness, smoothness, suppleness, and a silky hand feel to fabrics.

Solubility : Easily dispersible in water

Other Names : Silicon Softener, Silicone Softener Emulsion

Softner WC100 (Cationic Softener)

Application Method : Added in the final rinse bath, can be used in both exhaust and padding applications

Shelf Life : 12 Months

Type : Other, Cationic

Feature : Imparts excellent softness, smooth handle, and lubricity to fabric; nonyellowing; compatible with optical brightening agents

Solubility : Easily dispersible in water

Other Names : Softner WC100, Fabric Softener

Textile Smoothness Softener

Application Method : Padding, Exhaust, Spray, or Dipping methods

Shelf Life : 12 Months

Type : Other, Cationic Softener

Feature : Imparts smoothness and a soft hand feel to fabrics

Solubility : Easily dispersible in water

Other Names : Fabric Softener, Textile Softening Agent

|

WORLDTEX SPECIALITY CHEMICALS

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry